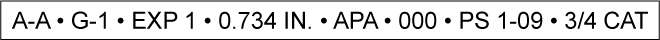

- A-A

-

A sanded plywood panel with A-grade face and back plies and D-grade inner plies. Bond classification is Exposure 1. Commonly used for cabinets, built-ins, furniture, partitions and other interior or protected applications where a smooth surface or appearance quality on both sides is important.

Back to Top

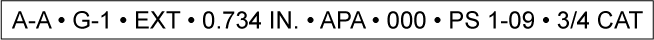

- A-A Exterior

-

A sanded plywood panel with A-grade face and back plies and C-grade inner plies. Bond classification is Exterior. Commonly used for fences, built-ins, signs, boats, cabinets, commercial refrigerators, shipping containers, tanks, tote boxes, ducts and other exterior or high moisture applications where a smooth surface or appearance quality on both sides is important.

Back to Top

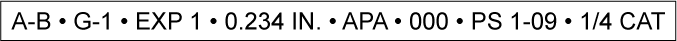

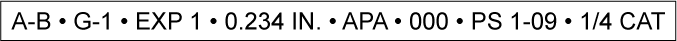

- A-B

-

A sanded plywood panel with A-grade face, B-grade back and D-grade inner plies. Bond classification is Exposure 1. Commonly used as a substitute for A-A where the appearance of one side is less important.

Back to Top

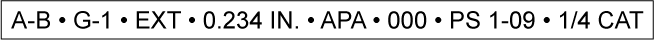

- A-B Exterior

-

A sanded plywood panel with A-grade face, B-grade back and C-grade inner plies. Bond classification is Exterior. Commonly used as a substitute for A-A Exterior where the appearance of one side is less important.

Back to Top

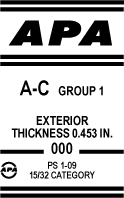

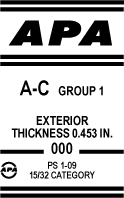

- A-C Exterior

-

A sanded plywood panel with A-grade face, C-grade back and C-grade inner plies. Bond classification is Exterior. Commonly used for soffits, fences, boxcar and truck linings, farm buildings, tanks, commercial refrigerators and other high-moisture applications where the appearance or smoothness of only one side is important.

Back to Top

- Acrylic Resin

-

An ingredient of water-base (latex) paints and stains. Synthetic resin with excellent weathering characteristics. Acrylics can be colorless and transparent, or pigmented.

Back to Top

- Adhesive

-

Adhesives are used in the manufacture of engineered wood products and in a variety of construction uses.

Used for manufacturing engineered wood products

APA trademarked plywood and LVL is manufactured using phenolic adhesive. APA trademarked OSB is manufactured using 1) phenolic adhesive, 2) isocyanate adhesive or 3) a combination with phenolic in the faces and isocyanate in the core.

APA trademarked I-joists use phenolic, melamine, and polyurethane adhesives in web to web and web to flange joints.

APA trademarked glulam beams use phenol-resorcinol and melamine adhesives in face and end joint bonds.

Used for building site or home projects

Urea or white glues are used in indoor, dry applications such as cabinets or furniture. Follow manufacturer’s recommendations.

Resorcinol glue is used in high moisture applications such as farm buildings or boats. Follow manufacturer’s recommendations.

Many adhesives, preferably in conjunction with nails or other fasteners, produce strong joints in wood structural panel construction. Type depends on purpose and exposure of finished product.

Other available adhesives include: Hot melt glues – for relatively small parts. Remember they cool and set quickly. Epoxy glues – limited use; most are not formulated for wood and are expensive. Contact Cements – useful for applying laminates and edge stripping to plywood. Not recommended for structural joints. Wall panel nonstructural adhesives – handy for applying decorative paneling or facing. May require a few nails per panel to position panels while glue sets. Structural adhesive is not recommended for applying wood structural panel wall sheathing. Casein glues – slow setting, permitting easier construction of difficult assemblies.

Construction adhesives are single-part elastomeric adhesives of various formulations, normally job site-applied with a caulking gun. They are designed for various applications such as nail-glued floors to improve floor performance and reduce squeaks.

Back to Top

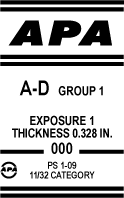

- A-D

-

A sanded plywood panel with A-grade face, D-grade back and D-grade inner plies. Bond classification is Exposure 1. Commonly used for paneling, built-ins, shelving, partitions and other interior or protected applications where the appearance or smoothness of only one side is important.

Back to Top

- AFG-01

-

A performance specification developed by APA for glues recommended for use in the APA Glued Floor System. AFG-01 requires that glues applied at the job site be sunlight resistant, strong under many moisture and temperature conditions, and able to fill gaps. Considered equivalent to ASTM D3498, Adhesive for Field-Gluing Plywood to Wood Framing.

Back to Top

- Aggregate-Coated Panel

-

A panel with stone chips embedded in a resin coating.

Back to Top

- Air-Dried

-

See Seasoning.

Back to Top

-

- Air-Barrier

-

A solid material that blocks air flow, used to enclose structures to prevent the passage of moisture laden air into the interior of the wall where it could condense on cold surfaces. May be placed on inside or outside wall surfaces of structure. Most often placed on outside surface where it also fulfills the code requirement for a weather barrier.

Back to Top

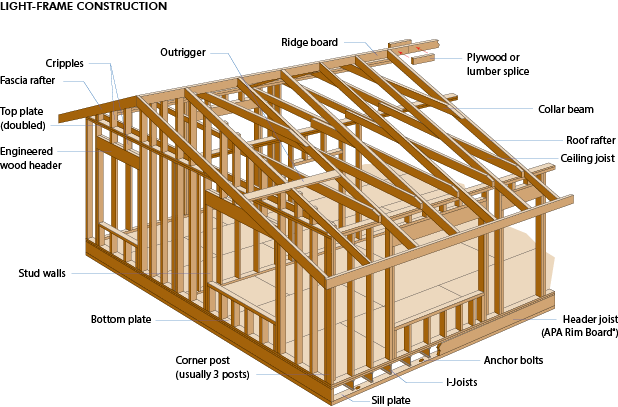

- Anchor Bolt

-

Bolts that tie the sill plate and thus the frame of a structure to its foundation.

Back to Top

- APA – The Engineered Wood Association

-

The trade organization representing manufacturers of plywood, OSB, glued laminated timber, I-Joists, Rim Board,® and structural composite lumber (SCL). The Association has three main functions: 1) research to improve wood structural panel (plywood and OSB) and other engineered wood products and systems, 2) quality inspection and testing to assure the manufacture of high quality wood structural panel and engineered wood products, and 3) promotion of engineered wood products and building systems. Commonly referred to as “APA,” and previously known as the American Plywood Association.

Back to Top

- APA Glued Floor System

-

A floor system developed by APA in which a single layer of APA RATED STURD-I-FLOOR panels (or subflooring in the case of double-layer construction) is glue-nailed to wood joists. The bond is so strong that floor and joists behave like an integral unit, greatly increasing floor stiffness and reducing floor squeaks and nail pops. Only construction adhesives conforming to APA specification AFG-01 or ASTM D3498 are recommended for use with the system. See T-Beam.

Back to Top

- APA Performance Rated Panels®

-

Panel products developed by APA, such as APA RATED SHEATHING, APA RATED STURD-I-FLOOR and APA RATED SIDING, designed and manufactured to meet performance criteria for specific end-use applications. APA Performance Rated Panels can be manufactured as conventional veneered plywood, as composites (veneer faces bonded to reconstituted wood cores), or as mat-formed panels (oriented strand board). The trademarks on APA Performance Rated Panels include a Span Rating denoting the maximum recommended spacing of supports over which the panel should be placed for the designated end use, and the exposure durability classification of the panel.

Back to Top

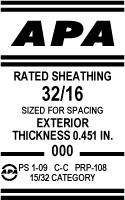

- APA RATED® SHEATHING

-

An APA Performance Rated Panel designed and manufactured specifically for residential and other light frame wall sheathing, roof sheathing and subflooring applications. APA RATED SHEATHING can be manufactured with Span Ratings of 12/0, 16/0, 20/0, 24/0, 24/16, 32/16, 40/20 and 48/24, in Performance Categories ranging from 5/16 to 3/4, and in two bond classifications – Exterior and Exposure 1.

Back to Top

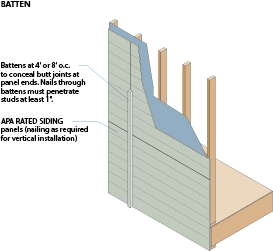

- APA RATED® SIDING

-

A grade designation covering APA proprietary siding products. Commonly used, in addition to siding, for fencing, soffits, wind screens and other exterior applications. Can be used for interior paneling. Can be manufactured as conventional veneered plywood, as a composite or as oriented strand board siding. Both panel and lap siding are available. Special surface treatment such as V-groove, channel groove, deep groove (such as APA Texture 1-11), brushed, rough sawn and texture-embossed (MDO). Span Rating (stud spacing for siding qualified for APA STURD-I-WALL applications) and face grade classification (for veneer-faced siding) indicated in trademark.

Brushed |

Rough sawn |

APA Texture One-Eleven® |

Kerfed |

Reverse board & batten |

Channel groove |

Back to Top

- Back-Out

-

See Nail Popping.

Back to Top

- Back-Priming

-

Application of a coat of primer to the back of a panel. Cabinet doors should be back-primed to prevent warping.

Back to Top

- Backstamp

-

The approved agency mark on the back of a panel. Unsanded and touch-sanded panels, and most panels with A or B faces on one side only, carry the APA trademark on the panel back. See also APA Trademark and Edgemark.

Back to Top

- Batten

-

A thin, narrow strip of plywood or lumber used to conceal or protect a joint between adjoining pieces of lumber or plywood.

Back to Top

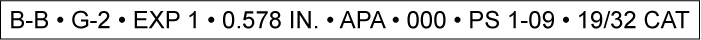

- B-B

-

A sanded plywood panel with B-grade face and back and D-grade inner plies. Bond classification is Exposure 1. Utility panel for interior or protected applications.

Back to Top

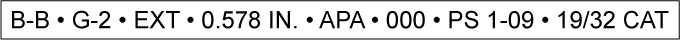

- B-B Exterior

-

A sanded plywood panel with B-grade face and back and C-grade inner plies. Bond classification is Exterior. Utility panel with solid paintable surface both sides.

Back to Top

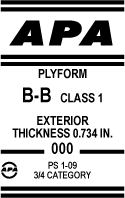

- B-B Plyform®

-

Concrete form grades with high re-use factor. Sanded both sides and mill-oiled unless otherwise specified. Special restrictions on species. Also available in HDO for very smooth concrete finish, in STRUCTURAL I (all plies limited to Group I species), and with special overlays. Bond Classification is Exterior.

Back to Top

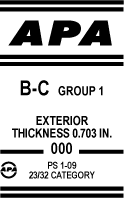

- B-C Exterior

-

A plywood panel with sanded B-grade face, C-grade back and C-grade inner plies. Bond classification is Exterior. Utility panel for farm service and work buildings, boxcar and truck linings, containers, tanks, agricultural equipment, as a base for exterior coatings, etc.

Back to Top

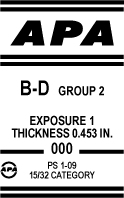

- B-D

-

A plywood panel with sanded B-grade face, D-grade back and D-grade inner plies. Bond classification is Exposure 1. Utility panel for backing, sides of built-ins, industry shelving, slip sheets, separator boards, bins, etc.

Back to Top

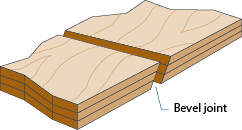

- Bevel

-

To cut panel edges or ends at an angle to make smooth mating joints between panels.

Back to Top

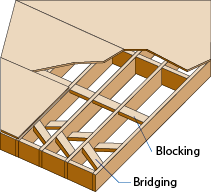

- Blocking

-

Short lumber segments nailed between major framing members to support edges of structural panels where they meet.

Back to Top

- Blow

-

A localized delamination caused by steam pressure buildup during the hot pressing operation. The steam may result from high moisture content of the veneer or strands, excessive glue spread, or high press temperatures.

Back to Top

- Boat Patch

-

See Repairs.

Back to Top

- Bond

-

To glue together, as veneers are “bonded” to form a sheet of plywood or a mat of strands to form OSB. Pressure is applied to keep mating parts in proper alignment. Glues used in panel manufacture require both heat and pressure to cure properly.

Back to Top

- Bond Classification

-

Bond classification ratings for APA wood structural panels designated in APA trademarks as Exterior or Exposure 1.

- Exterior panels have bonds capable of withstanding repeated wetting and redrying or long-term exposure to weather or other conditions of similar severity.

- Exposure 1 panels are suitable for uses not involving long-term exposure to weather. Panels classified as Exposure 1 are intended to resist the effects of moisture on structural performance as may occur due to construction delays or other conditions of similar severity.

Back to Top

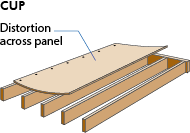

- Bow

-

Distortion of a wood structural panel so that it is not flat lengthwise. See Cup.

Back to Top

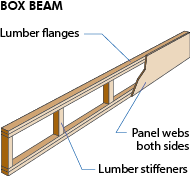

- Box Beam

-

A beam built of lumber and wood structural panel in the form of a long hollow box which will support more load across an opening than will its individual members alone. Lumber members form the top and bottom (flanges) of the beam, while the sides (webs) are plywood.

Back to Top

- Bridging

-

Short wood or metal braces or struts placed crosswise between joists to help keep them in alignment. Bridging may be solid or crossed struts.

Back to Top

- Brushed

-

An APA 303 Siding surface treatment. Brushed or relief-grain surfaces accent the natural grain pattern to create striking textures. Difficult to paint or stain. See APA RATED SIDING.

Back to Top

- Bundle

-

A unit or stack of wood structural panels held together for shipment with bands. Stack size varies throughout the industry, with the average stack running about 30 to 33 inches high. A bundle 30 inches high, for example, contains 120 sheets of 1/4-inch panels, 80 sheets of 3/8-inch panels, or 60 sheets of 1/2-inch panels.

Back to Top

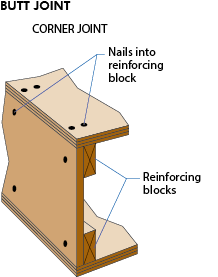

- Butt Joint

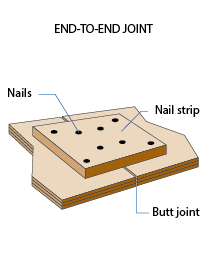

-

The joint formed when two parts are fastened together without overlapping. For end-to-end joints, use a nailing strip. For corner joints, nail directly into panel if it is at least 3/4-inch thick. If panel is thinner than 3/4-inch, use a reinforcing block.

Back to Top

- Caulk

-

Water resistant sealant used to fill joints or seams. Caulks are available as putties, ropes, or compounds extruded from cartridges.

Back to Top

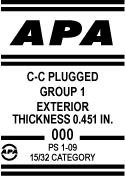

- C-C Plugged Exterior

-

A touch-sanded plywood panel with C-Plugged-grade face, C-grade back and inner plies. Bond classification is Exterior. Commonly used for severe moisture conditions, exterior balconies and decks, refrigerated or controlled atmosphere rooms, and boxcar and truck floors.

Back to Top

- C-D Plugged

-

A touch-sanded plywood panel with C-Plugged-grade face, D-grade back and inner plies. Bond classification is Exposure 1. Used for built-ins, cable reels, walkways and slave pallets.

Back to Top

- Center (Centers)

-

Inner ply or plies of a plywood panel whose grain runs parallel with that of the face and back plies.

Back to Top

- Center Gap

-

See Core Gap.

Back to Top

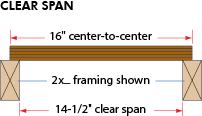

- Center-To-Center

-

See On-Center and Clear Span.

Back to Top

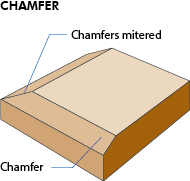

- Chamfer

-

The flat surface created by slicing off the square edge or corner of a piece of wood or panel.

Back to Top

- Channel Groove

-

An APA 303 Siding texture consisting of shallow grooves cut into panel faces during manufacture. See APA RATED SIDING.

Back to Top

- Checking

-

Wood exposed to alternating moist and dry conditions eventually develops open cracks or “checks.” Reduce checking by sealing panel edges before installation to minimize moisture absorption, and by using an elastomeric priming coat or resin sealer on the surfaces.

Back to Top

- Chord

-

Any of the outside members of a truss connected by web members. Also, may refer to perimeter members of a panel diaphragm.

Back to Top

- Circular Plug

-

See Repairs.

Back to Top

- Class I

-

See B-B Plyform.

Back to Top

- Clear Span

-

Distance between inside faces of supports.

Back to Top

- Code

-

See Model Code.

Back to Top

- COM-PLY®

-

APA proprietary trade name for APA member-produced composite panels. See APA Performance Rated Panels and Composite Panel.

Back to Top

- Component

-

A glued and/or nailed structural assembly of wood structural panels and lumber, such as a stressed-skin panel. Also describes prefabricated building sections in panelized construction.

Back to Top

- Composite Panel

-

A veneer-faced panel with a reconstituted wood core. See APA Performance Rated Panels and COM-PLY.

Back to Top

- Concentrated Load

-

See Loads.

-

Back to Top

- Concrete Form

-

Mold into which concrete is poured to set. Plywood provides tough, durable, easy-to-handle, split-resistant and lightweight concrete forms. It can be bent for curved forms and liners, and its natural insulating properties help moderate temperature variations for more consistent curing. Almost any APA trademarked plywood can be used in concrete formwork applications, but PLYFORM is specifically manufactured for that purpose. See B-B Plyform.

Back to Top

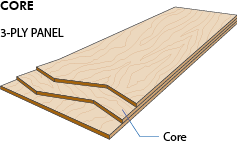

- Core (Cores)

-

In conventional plywood, inner plies whose grain runs perpendicular to that of the outer plies. See Ply.

Back to Top

- Core Gap (Center Gap)

-

An open veneer joint extending through, or partially through, a plywood panel. Product Standard PS 1 specifies that the average of all gaps shall not exceed 1/2 inch, and that every effort be made to produce closely butted core joints.

Back to Top

- Crawl Space

-

A space often about two feet high beneath a house floor allowing access to plumbing or wiring. See also PIRF.

Back to Top

- Cripple

-

Any vertical framing member cut less than full length, as in cripple studs under a window opening.

Back to Top

- Crossband (Cores)

-

In plywood, the veneer layers with grain direction perpendicular to that of the face plies. See Core.

Back to Top

- Cross Laminated Timber (CLT)

-

A prefabricated solid engineered wood panel made from at least three layers of solid-sawn lumber or structural composite lumber (SCL) that are stacked crosswise and bonded together with structural adhesives to form a solid, rectangular-shaped panel that is intended for construction applications, including roofs, floors and walls in residential and nonresidential buildings. Orthogonally bonding the layers increases the structural and dimensional stability of the product as a slab or wall.

Back to Top

- Cross Cutting

-

Sawing wood across the grain. Because the wood in wood structural panels is either cross-laminated or randomly oriented, any cut made in a wood structural panel is a cross cut. Always use a cross cut saw when hand- or power-sawing wood structural panels.

Back to Top

- Cup

-

Crosswise distortion of a wood structural panel from its flat plane. See Bow.

Back to Top

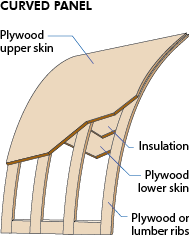

- Curved Panel

-

Stressed-skin or sandwich panels curved to various degrees of arc. Used in roof construction.

Back to Top

- Eave

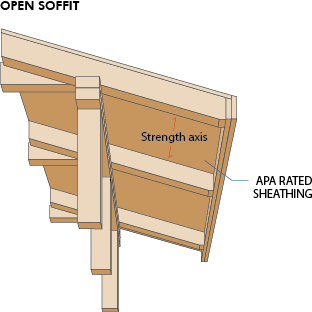

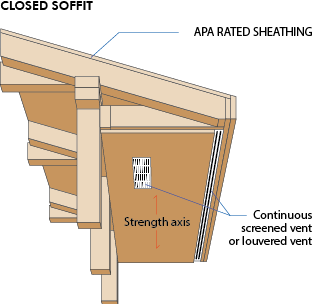

-

The edge of a roof that extends beyond or overhangs a wall. The underside of an eave may form an “open soffit.” Textured panels, applied face down to eave rafters as roof sheathing, give open soffits a decorative finished surface. See Soffit.

Back to Top

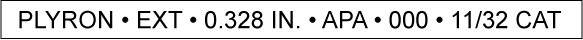

- Edgemark

-

APA trademark stamped on the panel edge. Appears on sanded grades with B-grade or better veneer faces, PLYRON, MARINE, and panels with overlaid surfaces on both sides.

Back to Top

- Edge Sealing

-

Application of a coating (e.g., sealant, paint) to the edges of a wood structural panel to reduce its water absorption. Edge seal before painting the panel surface if panel edges will be exposed to repeated wetting and drying.

Back to Top

- Edge Spacing

-

Back to Top

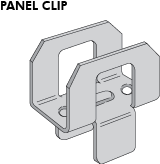

- Edge Support

-

Support, such as panel clips or lumber blocking, installed between framing members at wood structural panel edges to transfer loads from one panel to the other across the joint. Panels with tongue-and-groove edges can be used in many applications without additional edge support.

Back to Top

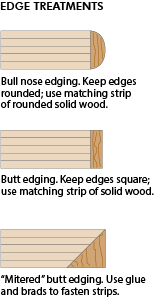

- Edge Treatment

-

Edge finishing method, such as banding with wood or plastic, or filling with putty or spackle.

Back to Top

- Edge Void

-

A panel defect in which the edge or end of an inner ply has split or broken away during manufacture, leaving a gap in the edge of the plywood panel.

Back to Top

- Embossed

-

A panel surface treatment. Heat and pressure against a master pattern impress a variety of textured effects into panel surfaces, which remain smooth and paintable.

Back to Top

- End Grain

-

The end of a piece of wood exposed when the wood fibers are cut across the grain. All wood structural panel edges are end grain, and should be finished accordingly.

Back to Top

- End Spacing

-

See Panel Spacing.

Back to Top

- Engineered 24" Framing

-

A building system using wood structural panels over lumber framing spaced 24 inches on center in walls, floors and roof. The system’s series of in-line frames – trusses, studs and joists – provide cost-effective materials utilization and simpler, faster construction. It is recognized by major model codes.

Back to Top

- Engineered Wood Products

-

Structural wood products manufactured by bonding together wood strands, veneers, lumber or other forms of wood fiber to produce a larger and integral composite unit with superior performance characteristics. These high performance building components achieve predictable and reliable performance characteristics with the efficient use of natural resources.

Back to Top

- Expansion

-

Moisture absorption causes wood to expand. Spacing between panel edges and ends is recommended to allow for any possible panel swelling. See Panel Spacing.

Back to Top

- Exposure 1

-

See Bond Classification.

-

Back to Top

- Exterior

-

PS 1 exposure bond classification term for plywood manufactured for permanent outdoor or marine use. See Bond Classification.

Back to Top

- Face

-

The highest-grade side of any veneer-faced panel that has outer plies of different veneer grades. Also, either side of a panel where grading rules draw no distinction between faces. For example, the face of an A-C panel is the side with the A-grade outer ply. Both sides of an A-A or B-B panel are referred to as faces.

Back to Top

- Face-Checking

-

Partial separation of wood fibers parallel to grain in the wood or veneer surfaces of panels caused chiefly by the strains of weathering and seasoning. See Checking.

Back to Top

- Face Grain

-

Direction of the grain of the outer ply (face) of a veneer-faced panel in relation to its supports. A panel’s greatest stiffness and strength is parallel to the face grain. Therefore, in construction, run the face grain or long dimension of the panel across supports for greatest stiffness and strength.

Back to Top

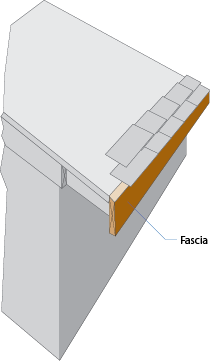

- Fascia

-

Wood or plywood trim used along the eave or the gable end of a structure.

Back to Top

- Fiberglass-Reinforced Plastic (FRP)

-

A tough, scuff-resistant plywood coating made of glass or other fibers combined with resins. These coated panels (composite) are used in truck and trailer bodies, containers and concrete forms. Seamless panels 40 feet long and longer can be produced as trailer sidewalls or roofs. Or, a very strong strip of glass or other fibers and resin that is applied to bottom of glulam timbers to increase the strength and stiffness properties of the glulam beam.

Back to Top

- Filler

-

A material for filling nail holes, checks, cracks or other blemishes in surfaces of wood before application of paint, varnish or other finishes.

Back to Top

- Finishes

-

Stains, paints or sealers which protect, color or enhance the natural beauty of wood structural panels.

- Exterior finishes primarily protect siding and maintain its appearance. They minimize the weathering action which roughens and erodes the surface of unfinished wood. Different finishes give varying degrees of protection so the type, quality, quantity and application must be considered to achieve the desired performance. All exterior panel edges should be sealed if the panels will be painted or stained. Sealing while panels are stacked is easiest. Exterior finishes recommended for wood structural panels include semi-transparent stain, solid-color stain and acrylic latex paint.

- Interior finishes: Preparation is minimal. Overlaid (MDO and HDO) plywood needs no preparation; sanded and textured grades require only touch-sanding. Recommended interior finishes include oil base paint, latex paint, stain and sealer.

Back to Top

- Fire-Rated Systems

-

Wall, floor and roof construction of specific materials and designs that has been tested and rated according to fire safety criteria (e.g., flame spread rate and fire resistance). Testing and approval are performed by agencies such as Underwriters Laboratories, Inc. A one-hour rating, for example, means that an assembly similar to that tested will neither collapse nor transmit flame or high temperature for at least one hour after a fire starts. Wood structural panels are an approved material in a number of fire-rated designs. See Flame Spread.

Back to Top

- Fire-Retardant-Treated (FRT)

-

Chemical treatment of wood and plywood to retard combustion. Plywood is pressure-impregnated with fire retardant chemicals mixed in water in accordance with American Wood Protection Association (AWPA) Standards U1 and T1. NOTE: Span Ratings and load capacities are based on untreated panels, and may not apply following fire-retardant treatment. Obtain structural performance characteristics of FRT panels from the company providing the treatment and redrying service.

Back to Top

- Flame Spread

-

The spread of fire along the surface of a material. Flame spread ratings are expressed in numbers or letters and are used in building code interior finish requirements.

Back to Top

- Flange

-

Top and bottom longitudinal members of a beam. Box beams and I-joists are fabricated with lumber or engineered wood flanges (top and bottom) and wood structural panel webs (sides). See Box Beam and I-Joist.

Back to Top

- Flashing

-

See Z Flashing.

Back to Top

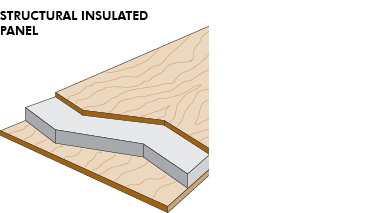

- Foam Core

-

Center of a wood structural panel-faced “sandwich&rd panel. Liquid plastic foamed into all spaces between the panels serves to both insulate and support the component skins. Or wood structural panel skins are pressure-glued to both sides of rigid plastic foam boards or billets. See Sandwich Panel and Structural Insulated Panel.

Back to Top

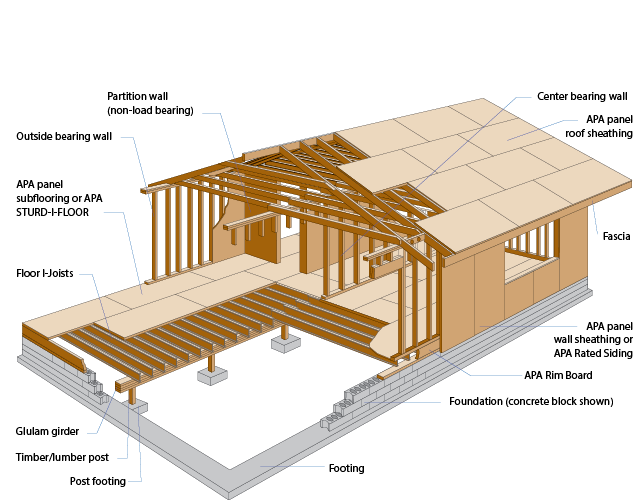

- Footing

-

The base for foundation walls, posts, chimneys, etc. The footing is wider than the member it supports, and distributes the weight of the structure to the ground over a larger area to prevent settling.

Back to Top

- Formaldehyde

-

Formaldehyde is a naturally occurring, organic molecule that can be irritating at high concentrations. It is true that some adhesives are known to emit formaldehyde. But engineered wood products are made with moisture-resistant adhesives that are associated with very low emission rates.

Back to Top

- FRP

-

See Fiberglass-Reinforced Plastic.

Back to Top

- FRT

-

See Fire-Retardant-Treated.

Back to Top

- Frame Construction

-

See Light-Frame Construction.

Back to Top

- Furnish

-

Wood-based material such as flakes or strands, including additives, such as adhesive and wax, used to manufacture OSB.

Back to Top

- Furring

-

Process of leveling parts of a ceiling, wall or floor by means of wood strips, called furring strips, before adding panel cover.

Back to Top

- Girder

-

A large horizontal beam which supports interior walls or joists. Most wood frame houses have a lengthwise center girder that supports the joists and floor panels. Girders can be timber or engineered wood. See Light-Frame Construction.

Back to Top

- Glue

-

See Adhesive.

Back to Top

- Glue-Nailed (Nail-Glued)

-

Gluing wood structural panel joints and connections with pressure provided by nailing. For most effective fastening, pieces should meet continuously along their joint. Apply glue to one or both surfaces according to manufacturer’s directions, then press surfaces together and nail in place. For work such as cabinets or drawers, or whenever possible, joint should be clamped as well as nailed to maintain pressure until glue sets.

Back to Top

- Glued Floor System

-

Back to Top

- Glueline

-

The adhesive joint formed between veneers in a plywood panel or between face veneers and core in a composite panel (primary glueline), or between lumber and wood structural panel parts in an assembly such as a component (secondary glueline).

Back to Top

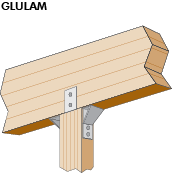

- Glulam

-

Short for structural glued-laminated timber – large beams fabricated by bonding layers of specially selected lumber with strong, durable adhesives. End and edge jointing permit production of longer and wider structural wood members than are normally available. Glulam timbers are used for many types of residential and commercial construction.

Back to Top

- Grade

-

Refers to the letter-graded quality of veneers used in plywood manufacture (N, A, B, C-Plugged, C and D), or to particular panels, e.g., A-A, Underlayment, etc. See also Veneer Grade

Back to Top

- Grain

-

The natural growth pattern in wood. The grain runs lengthwise in the tree and is strongest in that direction. Similarly, grain usually runs the long dimension in a panel of plywood or OSB, making it stronger in that direction. Wood structural panels should therefore usually be applied with the long dimension perpendicular to (across) supports.

Back to Top

- Grain Raise

-

The condition on the surface of a plywood panel resulting from harder or denser wood fibers swelling and rising above softer surrounding wood.

Back to Top

- Groove

-

One of the surface treatments frequently given to textured siding in which a series of narrow, parallel channels are cut into the surface of the panel. Grooving is available in a variety of widths and spacings on several surface textures. See APA RATED SIDING and Tongue-and-Groove Joint.

Back to Top

- Group Number

-

Plywood is manufactured from over 70 species of softwood. These species are classified according to strength and stiffness under manufacturing standard PS 1 into Groups 1 through 5. Group 1 woods are the strongest. The group number of a particular panel is determined by the weakest (highest numbered) species used in face and back (except for some thin panels where strength parallel to face grain is unimportant).

Back to Top

- Growth Ring

-

A tree’s annual cross-sectional growth layer, including springwood and summerwood.

Back to Top

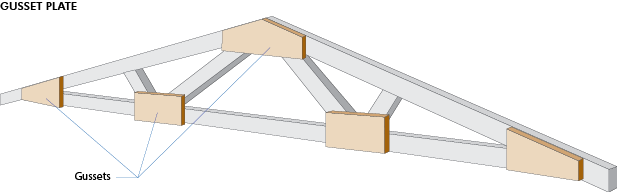

- Gusset Plate

-

A piece of wood structural panel connecting lumber members of a truss or other frame structure. Gussets may be applied to one or both sides of the joint. Plywood or OSB are used because of their great strength and split-resistance. Commonly used for repairs of metal-plate-connected wood trusses.

Back to Top

- Laminated Strand Lumber (LSL)

-

A composite of wood strand elements with wood fibers primarily oriented along the length of the member, where the least dimension of the wood strand elements is 0.10 inch (2.54 mm) or less and their average lengths are a minimum of 150 times the least dimension of the wood strand elements. LSL is one of several structural composite lumber (SCL) types. See SCL for more information.

Back to Top

- Laminated Veneer Lumber (LVL)

-

A composite of wood veneer sheet elements with wood fibers primarily oriented along the length of the member, where the veneer element thicknesses are 0.25 inch (6.4 mm) or less. LVL is one of several structural composite lumber (SCL) types. See SCL for more information.

Back to Top

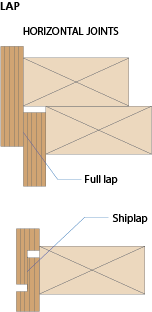

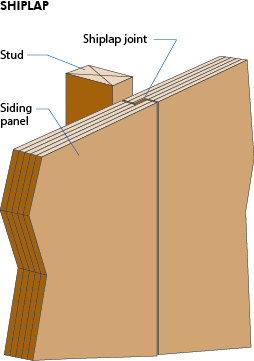

- Lap

-

To position adjacent objects so that one surface extends over the other. Term may designate a lap siding technique, in which each panel or piece overlaps the edge of the next lower panel. A shiplap joint unites two panels when half the thickness of each is cut away so that the two pieces fit together with outer faces flush.

Back to Top

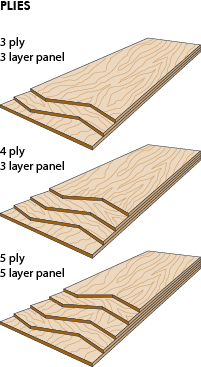

- Layer

-

In plywood, a layer consists of one or more adjacent plies having the wood grain in the same direction. For instance, four-ply panels always have three layers with both core plies at right angles to the faces. The two core plies are one layer and each face is a layer. In composite panels, the reconstituted wood portion is one layer and each face is a layer. See Ply, Oriented Strand Board.

Back to Top

- Lay-Up

-

The step in wood structural panel manufacture in which veneers or reconstituted wood layers are “stacked” in complete panel “press loads” after gluing and before pressing. Also the construction of the panel.

Back to Top

- Light-Frame Construction

-

Construction in which the structural parts are wood or dependent on a wood framework for support. Typically, lumber framing is sheathed with wood structural panels for roofs, walls and floors. The classification of light-frame construction remains the same in building codes even when masonry covering is applied on exterior walls.

Back to Top

- Live Loads (L.L.)

-

See Loads.

Back to Top

- Loads

-

The weight or pressure a structure carries or sustains, which must be considered in building design. Uniform loads are evenly distributed over a large area, usually the entire surface of a panel. Concentrated loads are applied over a very small area (for example, by a piano leg). Dead loads are stationary, permanent loads; that is, the weight of all the material used in construction of the building (or section). Live loads are planned loads the structure must carry under normal conditions, such as people or furniture and equipment, that would be moved across the structure’s surface. These loads are generally assigned by the building code for the type of structure; for example, a heavy-equipment storage warehouse, a house or an office building. Live loads are generally considered to be uniform loads. Environmental loads include wind, snow and earthquake.

Back to Top

- Lumber Core

-

Plywood manufactured with a core composed of lumber strips. The face and back (outer) plies are veneer.

Back to Top

- P & TS

-

Plugged and touch-sanded face of a plywood or composite panel.

Back to Top

- Paints

-

See Finishes.

-

Back to Top

- Panel Clip

-

Specially shaped metal device for supporting panel edges to reduce differential deflection in roof construction.

Back to Top

- Panel Performance Category

-

A recent emphasis on compliance with the Weights and Measures of the National Institute of Standards and Technology has led to the designation of Performance Category in lieu of nominal panel thickness for wood structural panels. As an example, a panel formerly identified as 3/8-inch thickness, is now designated as 3/8 Performance Category. This change has no impact on the design values, use recommendations and qualification or manufacturing requirements of the wood structural panels. See APA RATED SHEATHING and APA RATED STURD-I-FLOOR.

Back to Top

- Panel Spacing

-

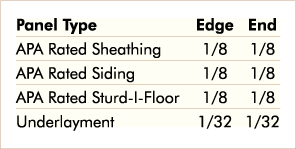

The gap left between installed panels in a structure. Panels in floor, wall or roof deck construction should be spaced to allow for any possible expansion due to changing moisture absorption levels. Proper spacing helps prevent buckling and warping. APA spacing recommendations are shown in the table below. See Sized for Spacing.

Back to Top

- Paneling

-

Wood panels joined in a continuous surface, especially decorative panels for interior wall finish. Textured plywood in many varieties is often used as interior paneling either in full wall sections or accent walls. See APA RATED SIDING for textured plywood used as paneling.

Back to Top

- Panelized Construction

-

Building components fabricated in wall, floor, or roof sections, etc., to be assembled into a completed structure at the building site. Panelized construction speeds erection and cuts on-site labor costs. It offers the high quality available through controlled factory production and inspection procedures.

Back to Top

- Parallel Strand Lumber (PSL)

-

A composite of wood strand elements with wood fibers primarily oriented along the length of the member where the least dimension of the wood strand elements is 0.25 inches (6.4 mm) or less and their average lengths are a minimum of 300 times the least dimension of the wood strand elements. PSL is one of several structural composite lumber (SCL) types. See SCL for more information.

Back to Top

- Patch

-

See Repairs.

Back to Top

- PCUF

-

See Plugged Crossband Under Face.

Back to Top

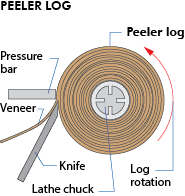

- Peeler Log

-

A specially selected log used to produce veneer. Peelers are debarked, then lathe-turned against a long knife blade which slices off a thin continuous ribbon of veneer then clipped to size, dried, graded, repaired and laminated into plywood panels or LVL billets.

Back to Top

- Performance Rated Panels®

-

See APA Performance Rated Panels.

Back to Top

- Performance Standard

-

A standard applying to panels such as APA RATED SHEATHING, APA RATED STURD-I-FLOOR and APA RATED SIDING. Panels manufactured to meet APA performance standards must satisfy rigorous, exacting performance criteria. See also Product Standard and APA Performance Rated Panels

Back to Top

- Permanent Wood Foundation

-

See Wood Foundation.

Back to Top

- PIRF (Perimeter-Insulated Raised Floor System)

-

Crawl space foundation-floor system where insulation is applied only to the inside of the perimeter foundation stem wall. The resulting system saves construction costs and gives superior energy performance.

Back to Top

- Pitch Streak

-

A localized accumulation of pitch in wood cells in a more or less regular streak.

Back to Top

- Plate

-

In wood frame construction, the horizontal lumber member on top and/or bottom of the wall studs which ties them together and supports the studs or rafters.

Back to Top

- Plug

-

See Repairs.

Back to Top

- Plugged Core

-

Inner ply construction of C-Plugged veneer pieces. Gaps between pieces of core should not exceed 1/2-inch per Product Standard PS 1. See Jointed Core.

Back to Top

- Plugged Crossbands Under Face (PCUF)

-

A designation denoting a PANEL of special construction, making it suitable for use as an UNDERLAYMENT, for example A-C (PCUF).

Back to Top

- Ply

-

A single veneer in a panel.

Back to Top

- Plyform

-

See B-B Plyform.

Back to Top

- Plyron®

-

A plywood panel manufactured with a hardboard face for an extra-smooth painting and tough wearing surface. May be Exposure 1 or Exterior. Exposure 1 PLYRON is available with a standard, tempered or treated hardboard surface and is manufactured of D-grade veneer except the ply directly under the hardboard surface, which must be C-grade. Exterior PLYRON is available with a tempered or treated surface and is manufactured with C-grade plies throughout. PLYRON is ideal for work surfaces, fixtures, built-ins, cabinets and doors, underlayment and industrial uses.

Back to Top

- Popping

-

See Nail Popping.

Back to Top

- Prefabricated

-

In housing, all parts constructed or fabricated at the factory so that final construction only involves assembling and uniting standard parts at the job site. Commonly abbreviated as prefab. See Panelized Construction.

Back to Top

- Prefinished

-

A ready-to-use panel with factory-applied finish – paint, overlays or coatings.

Back to Top

- Preframed

-

Panelized building in which wall, floor or roof sections are framed and sheathed at the factory.

Back to Top

- Preprimed

-

A panel with a factory-applied primer or undercoat needing only final finish after installation.

Back to Top

- Preservatives

-

Products which prevent wood-deterioration due to weather exposure, excessive moisture or insect attack. Treatments range from chemical pressure-impregnation, as for wood foundations, to application of paints or sealers.

Back to Top

- Pressure-Preservative Treated

-

Wood treated with preservative or by pressure-injecting treating solutions into wood cells. See Wood Foundation.

Back to Top

- Primer

-

An undercoat applied to bare wood as a sealer and base for paint. See Finishes.

Back to Top

- Product Standard

-

An industry product manufacturing or performance specification. APA trademarks carrying the PS 1 or PS 2 mark are identification by the manufacturer that the panel has been produced in conformance with U.S. Product Standard PS 1, Structural Plywood or Voluntary Product Standard PS 2, Performance Standard for Wood-Based Structural-Use Panels. PS 1 is a detailed manufacturing specification and alternate performance standard developed cooperatively by the softwood plywood industry and the U.S. Department of Commerce. PS 1 requirements and a supplementary set of APA specifications help ensure that plywood manufactured by APA member mills maintains its consistently high quality. PS 2 is a similar standard, without the detailed manufacturing specification, that relies on performance testing to assure that the structural panels meet realistic, rigorous standards. Other product standards developed by APA include, but are not limited to, APA PRI-400 Performance Standard for APA EWS I-Joists, APA PRR-401 Performance Standard for APA EWS Rim Boards, ANSI/APA PRR 410 Standard for Performance-Rated Engineered Wood Rim Boards, ANSI/APA PRP 210 Standard for Performance-Rated Engineered Wood Siding and ANSI/APA PRG 320 Performance Standard for Cross-Laminated Timber.

Back to Top

- PRP

-

See APA Performance Rated Panels.

Back to Top

- Purlin

-

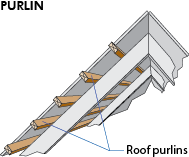

Subframing which supports roof decking where larger beams are main structural supports.

Back to Top

- PWP

-

Abbreviation for Permanent Wood Foundation. See Wood Foundation.

Back to Top

- R Value

-

A measurement of thermal resistance, or ability to retard heat transmission. Used to compute insulating effectiveness.

Back to Top

- Rabbet Joint

-

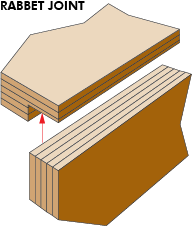

A joint formed by cutting a groove in the surface or along the edge of a board, plank or panel to receive another piece.

Back to Top

- Racking Resistance

-

The ability of a panel to resist forces in the panel’s plane tending to distort it from its rectangular shape.

Back to Top

- Radiant Barrier Panels

-

Engineered wood panels with a thin layer of highly reflective aluminum facing that minimize heat gains in homes and buildings by reducing the impact of solar radiation. Radiant barriers can be incorporated into walls and floors, but the most common application is in attics.

Back to Top

- Rafter

-

Sloping supporting member of a roof immediately beneath the sheathing.

Back to Top

- Raised Grain

-

See Grain Raise.

Back to Top

- RATED SHEATHING

-

See APA RATED SHEATHING.

Back to Top

- RATED SIDING

-

See APA RATED SIDING.

Back to Top

- Repairs

-

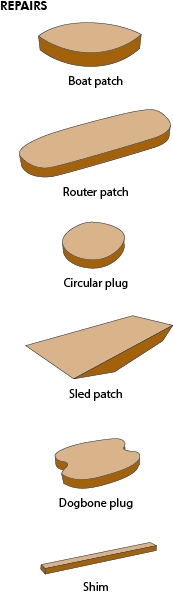

Any patch, plug or shim in a veneer. A patch is a sound wood insert or synthetic material to replace a defect in veneer. “Boat” patches are oval shaped with sides tapering to points or small rounded ends. “Router” patches have parallel sides and rounded ends. “Sled” patches are rectangular with feathered ends.

A plug may be a circular or dogbone shaped wood patch or a synthetic filler of fiber and resin to fill openings and provide a smooth, level, durable surface. A shim is a long narrow wood or synthetic repair not more than 3/16 inch wide. Various other shapes of plugs or patches may be encountered. PS 1 specifies sizes, shapes and numbers of allowable patches in given veneer grades.

Back to Top

- Resawn

-

See Rough Sawn.

Back to Top

- Resilient Floor Covering

-

Any of the vinyl or asphalt-base floor coverings (tile or sheet) with enough “give” to resist deformation or denting from dropped objects. Resilient floor coverings installed over APA STURD-I-FLOOR or UNDERLAYMENT panels with “sanded face” provide smooth, stiff floors for comfortable walking.

Back to Top

- Reverse Board and Batten

-

An APA 303 Siding surface treatment. Deep, wide grooves cut into textured siding surfaces during manufacture create striking, sharp shadow lines. See APA RATED SIDING.

Back to Top

- Ridge Beam

-

The top horizontal member of a sloping roof, against which the ends of the rafters are fixed or supported.

Back to Top

- Rigid Frame

-

Structural member functioning like an arch, comprised of studs and rafters fastened with plywood gussets. Rigid frame construction eliminates the need for ceiling or tie members.

Back to Top

- Rim Board®

-

The wood component that fills the space between the sill plate and bottom plate of a wall, or in second floor construction, between the top plate and bottom plate for two wall sections. The Rim Board is a continuously supported, full-depth structural element developed for use within a wood floor or roof assembly and performing a similar role as a starter or end joist when installed in a load bearing wall or non-load bearing wall perpendicular or parallel to the joist framing to transfer horizontal (shear) and vertical (compression) loads. It provides attachment for diaphragm sheathing, siding and/or exterior deck ledgers, and provides lateral support to floor or roof joists or rafters. APA Performance Rated Rim Boards® can be manufactured using plywood, oriented strand board (OSB), glued laminated timber (glulam) or structural composite lumber (SCL). Prefabricated wood I-joists may be used as a rim board. Rim Board is a registered trademark of APA.

Back to Top

- Ripping

-

Sawing wood in the direction of the grain.

Back to Top

- Rotary Peel

-

See Peeler Log.

Back to Top

- Rough Sawn

-

A decorative APA Siding treatment imparting a rough, rustic appearance by saw-scoring the surface of a panel during manufacture. Same as resawn. See APA RATED SIDING.

Back to Top

- Router Patch

-

See Repairs

Back to Top

- Sanded Panels

-

Exposure 1 or Exterior plywood panels factory-sanded for applications where smoothness and appearance are important. These panels – with N, A or B-grade faces – are ideal for furniture, cabinets, doors, fences, signs, etc. Sanded panels save time because they may be finished with little or no preparation.

Back to Top

- Sandwich Panel

-

See Structual Insulated Panel.

Back to Top

- Sapwood

-

Living wood of pale color near the outside of a log. Under most conditions, sapwood is more susceptible to decay than heartwood.

Back to Top

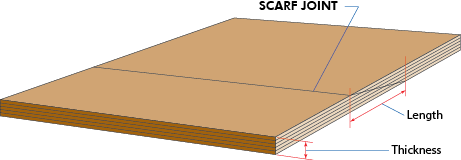

- Scarf Joint

-

An angled or beveled joint in plywood splicing pieces together. The length of the scarf is 5 to 12 times the thickness.

Back to Top

- SCL

-

See Structural Composite Lumber.

Back to Top

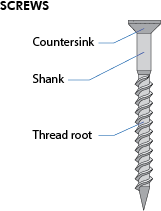

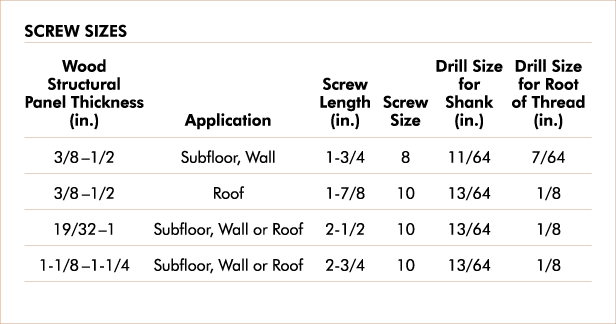

- Screws

-

Use wood screws for attaching wood structural panels where nails will not provide sufficient holding power. Sizes shown below are minimum; use longer screws where work permits. Lubricate screws with soap if they are hard to drive. If used for sheathing, use same spacing as recommended for nails.

Back to Top

- Seasoning

-

Removal of moisture from wood to improve its serviceability, sometimes by air drying – drying by air exposure without artificial heat – or kiln drying – drying in a heated chamber with artificial heat. Plywood veneers and OSB furnish are seasoned before lay-up and gluing into panels. See Furnish.

Back to Top

- Shear Wall

-

See Diaphragm.

Back to Top

- Sheathing

-

The structural covering, usually of wood panels or boards, on the outside surfaces of framing. It provides support for construction, snow and wind loads and forms backing for attaching exterior facing materials such as wall siding, roof shingles or underlayment in double-layer floors. APA RATED SHEATHING is recommended for conventional applications. See APA RATED SHEATHING.

Back to Top

- Shim

-

See Repairs.

-

Back to Top

- Shiplap

-

Jointing in which ends or edges are notch-milled to overlap and form a rabbet joint.

Back to Top

- Shop Cutting Panel

-

Panel rejected as not conforming to grade requirements defined in the Product Standard. Panel identification, a separate mark that does not mention the Standard, reads: “Shop Cutting Panel All Other Marks Void.” Normally a “shop” panel’s defect may be eliminated by cutting the panel into smaller pieces for applications not governed by building codes.

Back to Top

- Siding

-

See APA RATED SIDING.

Back to Top

- Sill Plate

-

The lowest framing member of a structure, resting on the foundation and supporting the floor system and the uprights of the frame.

Back to Top

- Single Floor

-

A single-layer wood structural panel flooring system combining subflooring and underlayment. See APA RATED STURD-I-FLOOR

Back to Top

- Single Wall

-

See APA RATED STURD-I-WALL.

Back to Top

- Sized For Spacing

-

A notation in APA RATED SHEATHING and RATED STURD-I-FLOOR trademarks indicating panels may be trimmed during manufacture to length and width tolerances of +0, −1/8 inch. This trimming is designed to encourage proper panel spacing. See Panel Spacing.

Back to Top

- Sled Patch

-

See Repairs.

Back to Top

- Soffit

-

The underside of the roof overhang. Wood structural panels are often used as finishing materials for soffits.

Back to Top

- Softwood

-

Wood of the coniferous or needleleaved trees – pine, fir, spruce, hemlock – as distinct from the hardwood of the deciduous or broadleaved trees – oak, ash, maple, walnut. The term has only a general reference to actual wood hardness. Construction and industrial plywood and other panel products may use either variety, but are more commonly manufactured of softwoods. See Hardwood.

Back to Top

- Solid Core

-

See Plugged Core

Back to Top

- Sound Transmission Class

-

See STC.

Back to Top

- Spacing

-

See Panel Spacing.

Back to Top

- Span Rating

-

APA RATED SHEATHING, APA RATED STURD-I-FLOOR and APA RATED SIDING carry numbers on their trademarks called Span Ratings. These denote the maximum recommended center-to-center spacing in inches of supports over which the panels should be placed in normal code-conforming construction. Except for APA RATED SIDING panels, the Span Rating applies when the long panel dimension or strength axis is across supports, unless the strength axis is otherwise identified on the panel. The Span Rating of APA RATED SIDING panels applies when panels are installed vertically (parallel to studs).

The Span Rating on APA RATED SHEATHING panels appears as two numbers separated by a slash, such as 32/16, 48/24, etc. The left-hand number denotes the maximum recommended spacing of supports when the panel is used for roof sheathing with the strength axis of the panel across three or more supports (two or more spans). The right-hand number denotes the maximum recommended spacing of supports when the panel is used for subflooring with the strength axis of the panel across three or more supports (two or more spans). A panel marked 32/16, for example, may be used for roof decking over supports up to 32 inches on center or for subflooring over supports up to 16 inches on center.

The Span Rating on APA RATED STURD-I-FLOOR and APA RATED SIDING panels appears as a single number. APA RATED STURD-I-FLOOR panels are designed specifically for single-floor (combined subfloor-underlayment) applications under carpet and pad and are manufactured with Span Ratings of 16, 20, 24, 32 and 48. The Span Ratings for APA RATED STURD-I-FLOOR panels, like those for APA RATED SHEATHING, are based on application of the panel with the strength axis of the panel across three or more supports (two or more spans). APA RATED STURD-I-FLOOR may be also used in roof decking applications.

Similarly, the single-number Span Ratings on APA RATED SIDING panels are the maximum recommended center-to-center spacings of studs (16 or 24 o.c.) when the panel is applied vertically direct to studs (or over nonstructural wall sheathing such as fiberboard, gypsum or rigid foam insulation sheathing). All RATED SIDING panels may be applied horizontally direct to studs spaced 16 or 24 inches on center, provided horizontal joints are blocked. When RATED SIDING is used over APA RATED SHEATHING or lumber, the Span Rating refers to the maximum recommended spacing of vertical rows of nails rather than studs.

Panels with a given Span Rating may be manufactured in more than one thickness and vice versa, because of varying panel compositions and configurations.

Back to Top

- Species Group

-

See Group Number.

Back to Top

- Stains

-

See Finishes.

Back to Top

- STC

-

Sound Transmission Class. A measure of the ability of a wall or floor assembly to reduce noise transmission.

Back to Top

- Stressed-Skin Panel

-

An engineered structural panel assembly for roof deck or floor applications built of plywood sheets glued to framing members. The quick-covering assembly has greater load carrying capacity than would its individual members if installed separately.

Back to Top

- Stringer

-

A lumber member supporting a series of cross members. Frequently applied to stair supports.

Back to Top

- Structural Composite Lumber (SCL)

-

Includes laminated veneer lumber (LVL), laminated strand lumber (LSL), oriented strand lumber (OSL) and parallel strand lumber (PSL). It is a family of engineered wood products created by layering dried and graded wood veneers, flakes or strands bonded with an exterior adhesive into blocks of material known as billets. The wood fibers are primarily oriented along the length of the wood composite. Cured in a controlled process, SCL is typically available in various thicknesses and widths and is easily worked in the field using conventional construction tools.

Back to Top

- Structural I

-

Unsanded grade for use where shear and cross-panel strength properties are of maximum importance, such as panelized roofs and diaphragms. All plies in Structural I plywood panels are special improved grades and panels marked PS 1 are limited to Group 1 species. Other panels marked Structural I Rated qualify through special performance testing. Manufactured with Exterior or Exposure 1 bond classification. See APA RATED SHEATHING.

Back to Top

- Structural Insulated Panel (SIP)

-

A section of layered construction made up of high-strength wood structural panel faces or “skins,” attached to both sides of low-density core materials such as plastic foam or honeycomb paper fillers. Sometimes referred to as sandwich panel or stress-skin panel.

Back to Top

- Stud

-

The basic vertical framing members of walls, usually 2x4 or 2x6. Studs are traditionally spaced 16 inches on center, sometimes 24 inches as in the Engineered 24" Framing System. See Span Rating.

Back to Top

- Sturd-I-Floor

-

See APA RATED STURD-I-FLOOR.

Back to Top

- Sturd-I-Wall

-

See APA STURD-I-WALL.

Back to Top

- Subflooring

-

APA RATED SHEATHING panels applied directly over floor joists which will receive an additional underlayment layer. Wood structural panels provide strength and stiffness. They also reduce the number of floor joints as compared with board sheathing. See Underlayment.

Back to Top

- Swelling

-

See Expansion and Panel Spacing.

Back to Top

- Synthetic Repairs

-

See Repairs.

Back to Top